EREMA Silicon Carbide Elements: the Most Efficient, Cost effective and Versatile Heating Elements on the Market.

EREMA silicon carbide (SiC) heating elements are manufactured by TOKAI Konetsu Kogyo Co., Ltd. (TKK) – the world’s largest manufacturer of SiC heating elements. TKK have been manufacturing EREMA SiC heating elements since 1936. TKK are dedicated to continuous product improvement and customer satisfaction focussing on energy savings and environmentally friendly products to provide high quality results.

EREMA silicon carbide electric heating elements are manufactured from high purity SiC grains and are designed to maximise performance at high temperature use operating in the range 500–1650 °C and in a wide spectrum of thermal processing furnaces or kilns as a radiant heat source. As the most efficient, cost-effective and versatile heating element on the market, EREMA silicon carbide elements are used in many types of industrial furnaces within the ferrous and non-ferrous metal heat treatment processes.

The continuous improvements are focused on “energy savings”, ”environmental aspects” by achieving good results at high temperatures with high quality products.

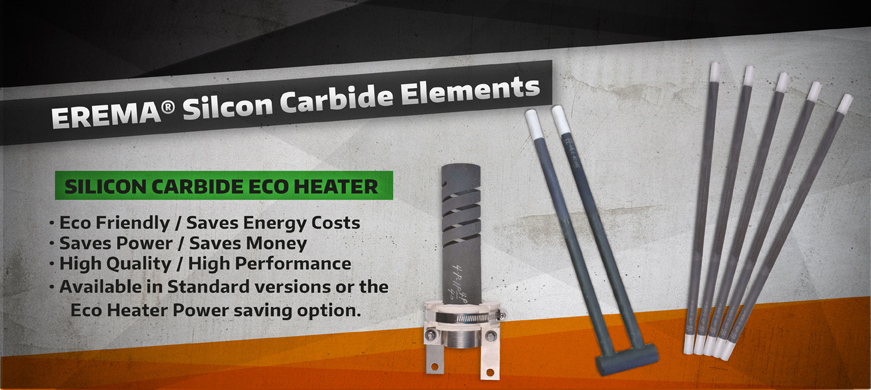

New EREMA Eco heater

The EREMA Eco heater elements use less power than conventional elements and the resulting cost savings can exceed the purchase price of the heating elements. Typical payback period can be as little as 12 months depending on the application and condition of the furnace. The unique element terminal design of the EREMA Eco heater reduces the heat lost from your furnace. Reduced losses mean lower electricity consumption, and that saves you money, It’s as simple as that. Reducing power not only cuts the electricity bill, but is also beneficial to the environment, reducing your carbon footprint by helping to lower the emission of greenhouse gases.

EREMA Eco heater elements are interchangeable with conventional silicon carbide elements. No capital costs, no need for new power supply, no furnace modifications. – Simply install EREMA Eco heater elements and start saving money today. In tests carried out under steady state conditions, EREMA Eco heater elements required 4–6 % less power than conventional silicon carbide elements to maintain a constant furnace temperature of 1200 °C.