Description

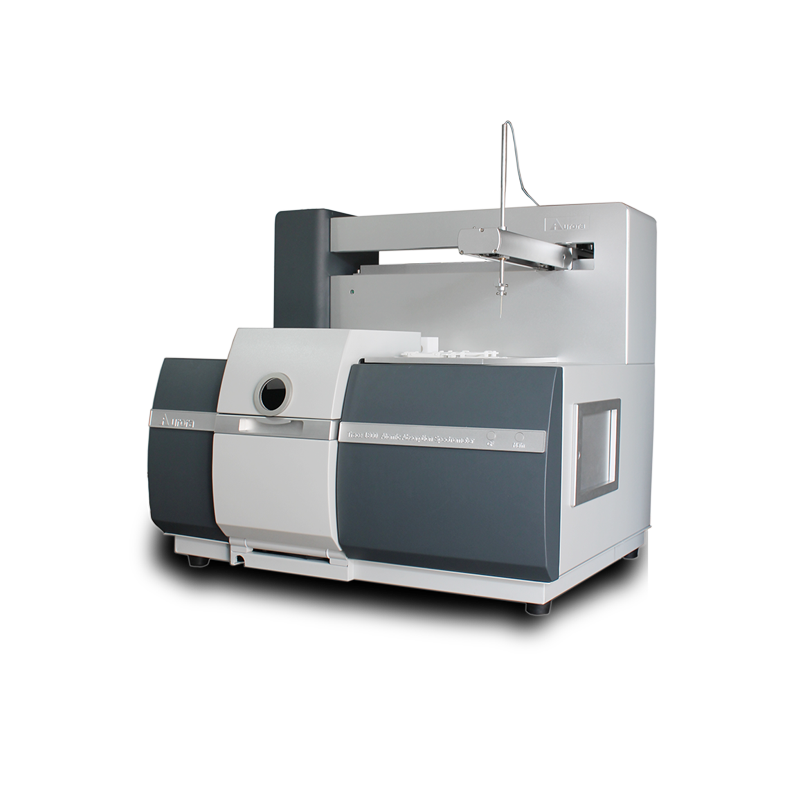

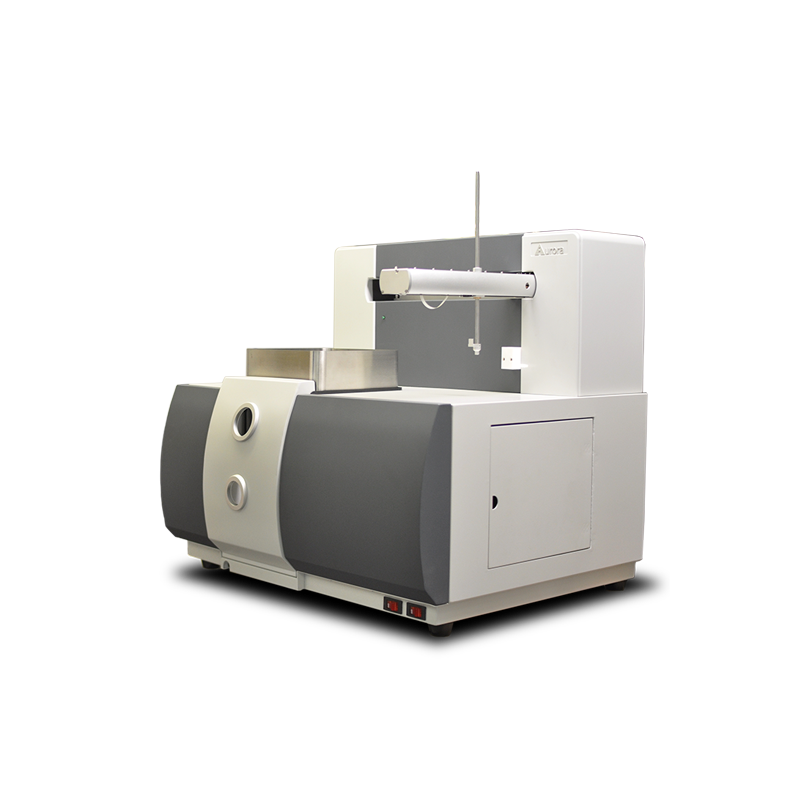

The transversely-heated graphite furnace tube provides industry-leading heating rates while sustaining high throughput efficiencies with Aurora’s Fast Dry technology. The universal XYZ autosampler enables automated, high throughput analysis from almost any container.

The TRACE Series combines excellent performance, reliable software and great values for a complete solution in trace metal analysis.

Overview

The atomic absorption spectrometer is the 3rd generation AAS instrument developed by Aurora. For more than 10 years, Aurora’s TRACE AI1200 has built a reputation in elemental analysis research, with unbeatable performance, sensitivity and flexibility.

These instruments are used in a variety of fields including environmental, agriculture, clinical, and mining. Standard configurations include the TRACE AI1200 Flame (F), TRACE AI1200 Flame/Graphite Furnace (F/GF), TRACE AI1200 Flame/Vapour Generation (F/VG) and TRACE AI1200 Flame/Graphite Furnace/Vapour Generation (F/GF/VG) enabling analyses at multiple concentration levels.

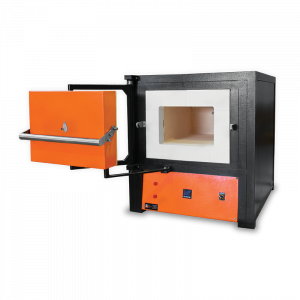

Atomisers

The configuration of the atomization compartment allows rapid changeover between atomization sources.

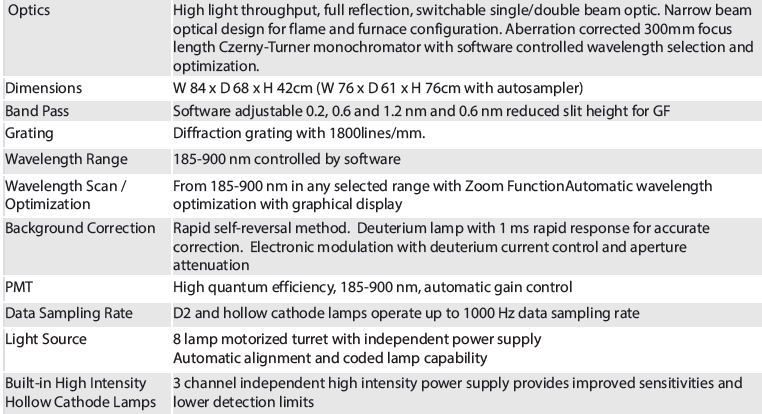

Spectrometer

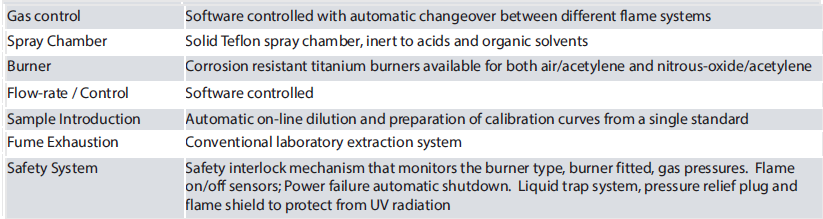

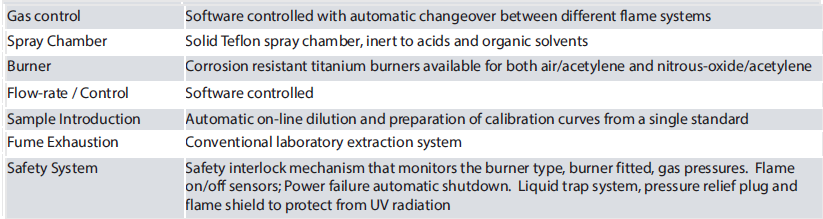

Flame

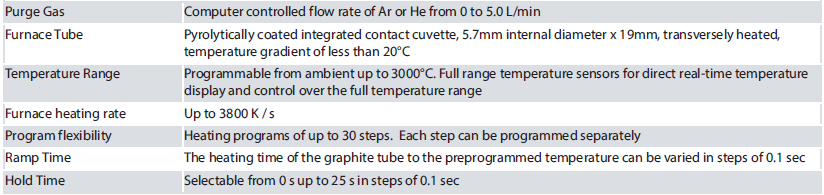

Transversely-heated Graphite Furnace

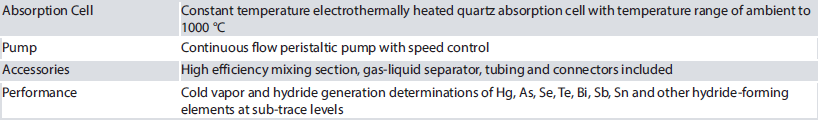

Vapor and Hydride Generator

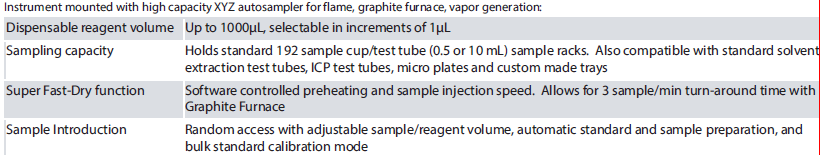

Auotsampler

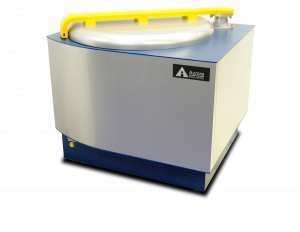

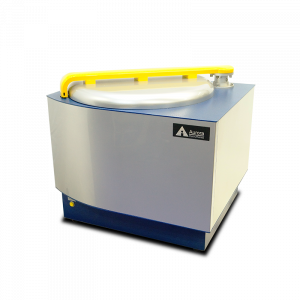

Overview

The TRANSFORM 800 is an automated, top-loading, closed vessel microwave digestion system offering high-pressure capabilities to enhance digestion quality while decreasing digestion time. This system is capable of simultaneously running up to 10 high-pressure closed vessels, providing a fast

and automated method to digest even the most difficult samples.

With simple one-step operation, full computer control of temperature and power, and monitoring of pressure, this cost-effective TRANSFORM 800 consolidates your AAS, AFS, ICP-AES, Hg-Analyzer, ICP-OES and ICP-MS applications. The TRANSFORM 800 provides optimal performance and reliable quality for sample preparation while leading the industry in

safety.

Closed vessel digestion:

The TRANSFORM 800 has capacity for 10 high-pressure vessels capable of digesting at a working pressure and temperature of up to 800 psi and 250°C. Temperature feedback control is achieved with a sealed thermocouple probe enabling fast and accurate digestion by monitoring pressure and directly sensing and controlling temperature. The TRANSFORM 800 microwave system is more cost effective than comparable systems but has equivalent safety and performance.

Computer Control:

The TRANSFORM 800 is a computer-controlled system. Its

software features real-time control of temperature, pressure monitoring, graphic display, automatic data storage, unlimited method storage, and complete record of instrument parameters.

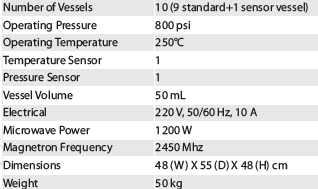

Specifications

Features

-

Direct sensing and control of sample temperature, and

monitoring of pressure in vessels to ensure reproducible

digestion -

Evenly distributed microwave field throughout the

chamber ensures uniform heat for each vessel -

On-line EPA protocols and methods directory, offering full

compliance with EPA methods -

Flexibility to program individual methods for specific

customizable sample preparation -

Automated recording of conditions during each digestion

reduces volatile element loss -

Prevents sample containment from the environment

-

Minimizes solvent consumption

Safety features

-

Sound, pressure-resistant heavy-duty oven chamber made of PFA-coated stainless steel

-

Top-loading, heavy duty automatic door with three level

protection and safety interlocks -

Spring loaded inner cavity of lid buffers the shock in the

event of heightened pressure. -

Over Pressure Valve on each vessel vents at pre-set pressure limits. In addition, each vessel also has a rupture disk, offering the highest level of safety for high-pressure situations

-

Residual vessel pressure can be released manually during

opening, providing extra safety to the user -

Digestion vessels are molded with engineering plastics

-

Continuous temperature control and pressure monitoring