Description

ADVANTAGES

Designed for large sample volumes

The HP-M1500 mill is ideal for grinding large sample quantities. Depending on the material density, the HP-M1500 can hold up to 1500 g of material with a diameter smaller than 5 mm. The large capacity of the HP-M1500 brings many advantages such as processing materials with large surface areas, improved sample representativeness and effective homogenization.

Tried and tested for numerous applications

Other advantages of the HP-M 1500 include a grinding process that can be fully controlled using program parameters, extensive standard equipment and numerous options. This makes the HP-M1500 suitable for a variety of different applications and materials including ores, concentrates, e-waste, catalysts, limestone and coal. The HP-M1500 was designed for stand-alone operation, connection to an input and output magazine or integration into a fully automated system.

Optimal grinding results

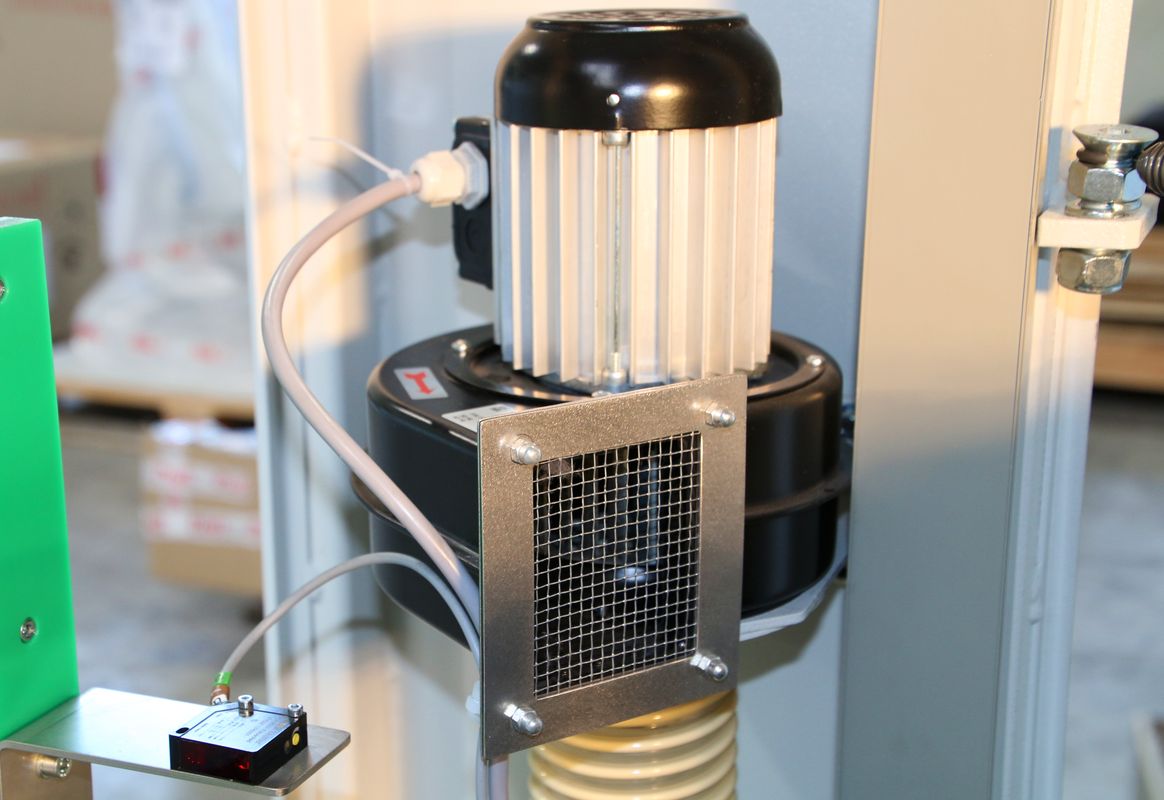

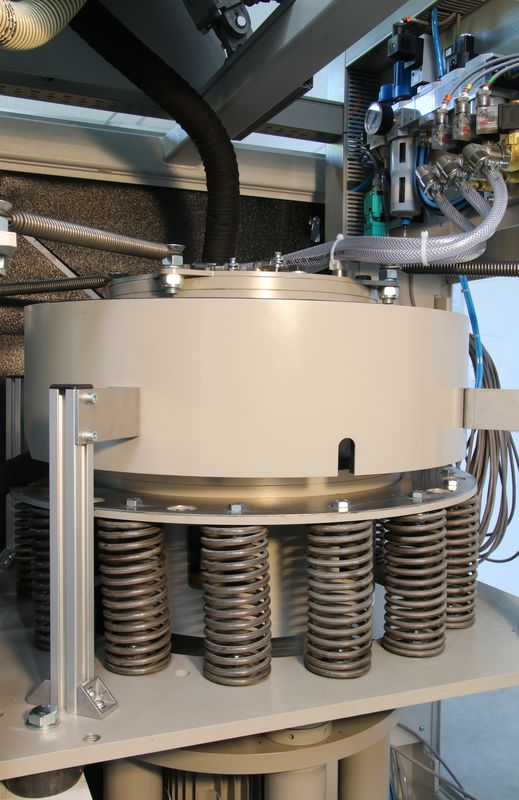

The HP-M1500 disc mill enables the efficient grinding of different materials with different properties and degrees of hardness – from soft to hard. To ensure effective horizontal circular movement without wobbling, the grinding vessel is mounted on a precisely balanced, spring-loaded unit. The rotational movements of the grinding vessel accelerate the grinding set contained therein due to centrifugal forces and initiate the comminution process, which is based on impact and friction.

The HP-M1500 is designed to ensure the target grain size for pulverizing samples within the shortest processing time. The respective machine parameters such as oscillation frequency can be controlled accordingly via the machine panel or the HERZOG Prepmaster software. Special grinding sets with grinding stone and grinding ring made of hardened chrome steel are available for the gentle grinding of particularly sensitive samples. For special applications, the HP-M1500 can be offered as a continuous mill for the continuous grinding of larger sample quantities.

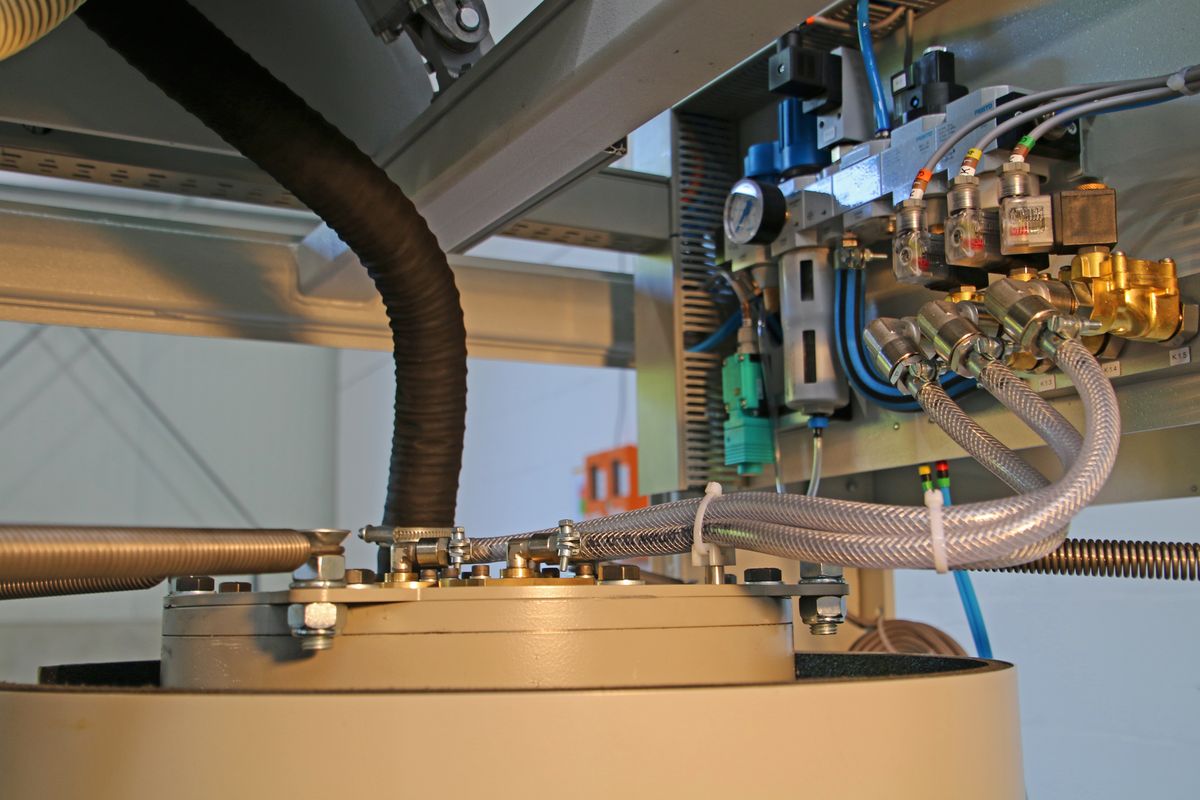

Effective cleaning

The machine is automatically cleaned after each sample preparation cycle. All machine parts that come into contact with the sample material are automatically cleaned with compressed air. Fine dust is removed by an external dust extraction (option), which can be controlled via the machine PLC. This reduces the risk of material carryover between successive samples to a minimum. For special requirements, the option of cleaning with solids such as: B. quartz sand or plastic granules are available. The container for the cleaning material can be placed next to the machine and easily filled by the operator. In addition, the HP-M1500 can be delivered with a fully automatic wet cleaning function.

OPTION

- Input magazine (8 or 30 cups)

- Grinding aid dosage (liquid)

- Load cell for input and output weight

- Temperature measurement

- Grinding vessel chrome steel 1500 cc